Which Slab Is Better Ribbed Slab Or Solid Slab (One Way 3.2.3.1 One-way Ribbed Slab : In one-way ribbed slab, loads are transferred in one direction, and the main reinforcement is distributed in the same direction of the load. With accurate to temperature and shrinkage, minimum of 33 bars diameter will be used in both direction and crossing each other over the blocks ( practically ). Figure 3.2

STRUCTURAL DESIGN 2 RIBBED (JOIST) HOLLOW POT

Hollow block and ribbed slabs. Analysis and Design of One-Way Slab Systems 11 Prof. Dr. Qaisar Ali Reinforced Concrete Design –II Department of Civil Engineering, University of Engineering and Technology Peshawar For purposes of analysis and design, a unit strip of one way slab, cut out at right angles to the supporting beams, may be considered as a rectangular beam of unit width, with a depth h and a span l a as shown, STRUCTURAL RIBBED CONCRETE SLABS The CUPOLEX® floor slab can be fully or partially suspended on piles, stem walls or grade/edge beams. Additional reinforced internal ribs are then used in the slab by introducing PONTEX®, the structural CUPOLEX® accessory to provide a structure capable of spanning between foundations or piles..

14/12/2016 · One Way Slab. One way slab is supported on two opposite side only thus structural action is only at one direction. Total load is carried in the direction perpendicular to the supporting beam. If a slab is supported on all the four sides but the ratio of longer span (l) to shorten span (b) is greater than 2, then the slab will be considered as View Ribbed_slab.pdf from MECHANICAL ME 201 at Jordan University of Science and Technology. One Way Ribbed Slab Analysis of One Way Ribbed Slab Area supported by one rib = (Ls) (s) Load for each rib

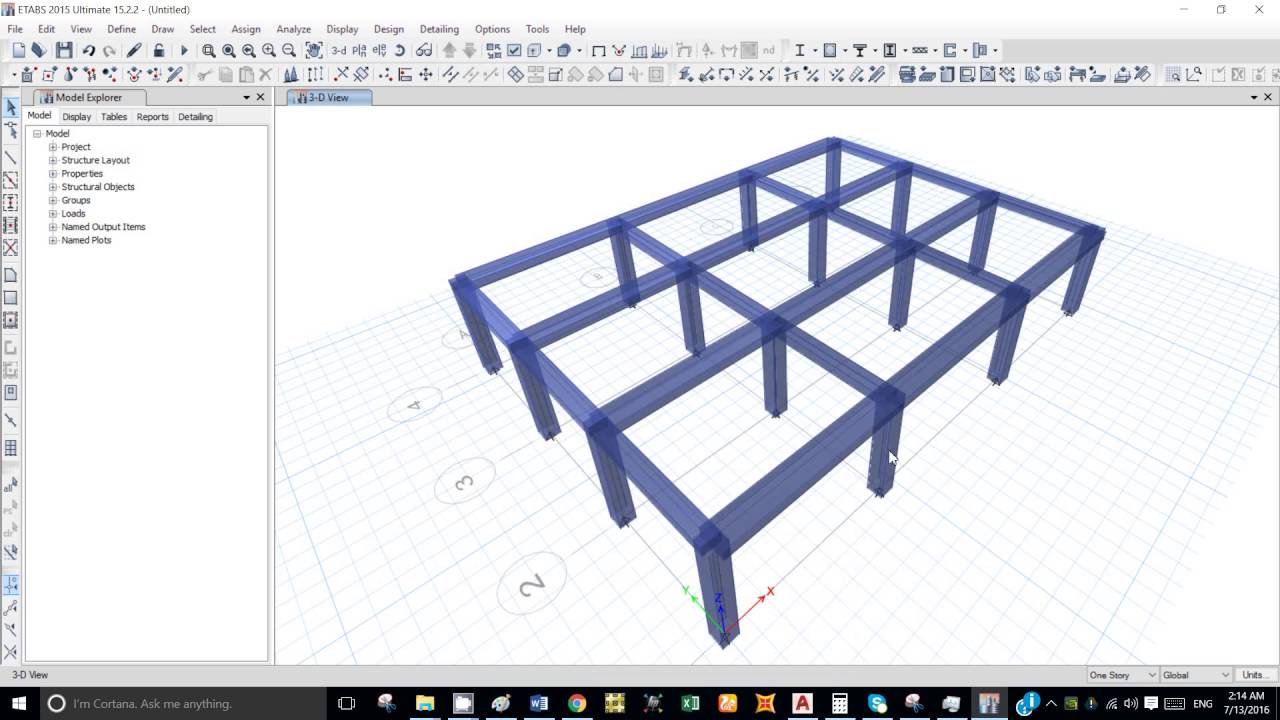

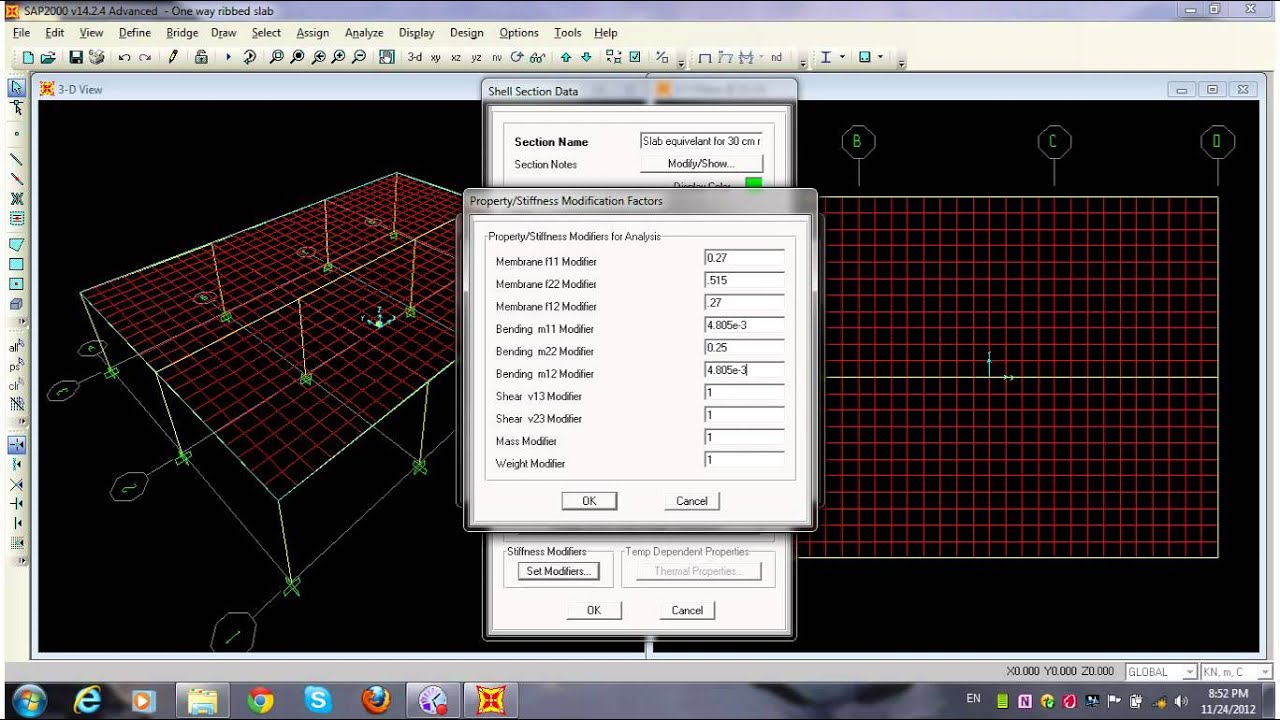

Mathematical structural analysis of one way ribbed slabs was introduced in this paper. The results of this analysis are compared with the results of the finite element method by SAP program. In SAP program, the model has been divided to frame elements "to represent ribs and beams" and shell elements "to represent the slab and solid part Minimum Depth. Minimum depth of the one-way concrete slab, most of the times is governed by deflection criteria. Sometimes the minimum depth is adequate as per flexure design, but if deflection criteria aren’t fulfilled such slabs will face vibration even under small loads like walking, jumping, etc.

Analysis of two- way ribbed and waffle slabs with hidden beams Article (PDF Available) in International Journal for Computational Civil and Structural Engineering Volume 4, No 3, 2014 · January Analysis and Design of Slabs, One way slabs, online free slab design, design of slabs one way, free slab design online, Design Procedure for One Way Slab Skip to content Civil Engineers PK

Ribbed slabs (One-way joists) Introducing voids to the soffit of a slab reduces dead weight and increases the efficiency of the concrete section. A slightly deeper section is required but these stiffer floors facilitate longer spans and provision of holes. Economic in the range 8 to 12 m. The saving of materials tends to be offset by some A corrugated slab is designed when the concrete is poured into a corrugated steel tray, more commonly called decking. This steel tray improves strength of the slab, and prevents the slab from bending under its own weight. The corrugations run in one direction only. A ribbed slab gives considerably more strength in one direction. This is

A corrugated slab is designed when the concrete is poured into a corrugated steel tray, more commonly called decking. This steel tray improves strength of the slab, and prevents the slab from bending under its own weight. The corrugations run in one direction only. A ribbed slab gives considerably more strength in one direction. This is Ribbed (Waffle) Slab System. Ribbed floors consisting of equally spaced ribs are usually supported directly by columns.They are either one-way spanning systems known as ribbed slab or a two-way ribbed system known as a waffle slab. This form of construction is not very common because of the formwork costs and the low fire rating. A 120-mm-thick

A corrugated slab is designed when the concrete is poured into a corrugated steel tray, more commonly called decking. This steel tray improves strength of the slab, and prevents the slab from bending under its own weight. The corrugations run in one direction only. A ribbed slab gives considerably more strength in one direction. This is In this post, I will go over the sixth example in our course that covers the analysis and design of reinforced concrete one-way slabs. The objective of this reinforced concrete design example is to design a one ribbed concrete joist floor system per ACI Code 318-11.

Ribbed slabs (One-way joists) Introducing voids to the soffit of a slab reduces dead weight and increases the efficiency of the concrete section. A slightly deeper section is required but these stiffer floors facilitate longer spans and provision of holes. Economic in the range 8 to 12 m. The saving of materials tends to be offset by some 8 one-way reinforced concrete ribbed slab panels where the main variables were the distance between the ribs and the thickness of the flange. The normative recommendations of NBR 6118, ACI 318 and EUROCODE 2 for the ultimate resistance of these slabs were evaluated. The experi -

Teaching two-way ribbed slab analysis and design using the MathCAD program Mohammed S. Al-Ansari University of Qatar Doha, Qatar ABSTRACT: In this article, the author presents a parallel approach to the traditional teaching method of two-way ribbed slabs. A corrugated slab is designed when the concrete is poured into a corrugated steel tray, more commonly called decking. This steel tray improves strength of the slab, and prevents the slab from bending under its own weight. The corrugations run in one direction only. A ribbed slab gives considerably more strength in one direction. This is

One-way Ribbed slab. Key component of one way ribbed slab : A. Topping Slab : 9.8.3.1 Slab thickness shall be not less than one-twelfth the clear distance between ribs, nor less than 50 mm. ( without filler ) We use t = 70 mm Abstract. The simplest routine structural element for illustration of design provisions in the Code is the one-way slab. A one-way slab is defined for purposes of this book as a flexural member with depth small relative to other dimensions, supporting (gravity) loads applied normal to and directly over its surface, spanning in one direction

ribbed slab design example pdf In order to demonstrate the application of the MathCAD program and to demonstrate its impact on teaching the analysis and design of two-way ribbed slabs.The number of strands in each rib is typically limited to one or two, with bottom rebar not exceeding two 5 12mm. Teaching two-way ribbed slab analysis and design using the MathCAD program Mohammed S. Al-Ansari University of Qatar Doha, Qatar ABSTRACT: In this article, the author presents a parallel approach to the traditional teaching method of two-way ribbed slabs.

Hollow block and ribbed slabs. 02/07/2015 · One-Way Concrete Slab Design Part 1 - Concept Explained and Minimum Slab Thickness - Canadian Code - Duration: 11:46. AF Math & Engineering 8,461 views, 3.2.3.1 One-way Ribbed Slab : In one-way ribbed slab, loads are transferred in one direction, and the main reinforcement is distributed in the same direction of the load. With accurate to temperature and shrinkage, minimum of 33 bars diameter will be used in both direction and crossing each other over the blocks ( practically ). Figure 3.2.

Ribbed slabs KASET KALIP

One-Way Reinforced Concrete Slabs SpringerLink. View Ribbed_slab.pdf from MECHANICAL ME 201 at Jordan University of Science and Technology. One Way Ribbed Slab Analysis of One Way Ribbed Slab Area supported by one rib = (Ls) (s) Load for each rib, Analysis and Design of Slabs, One way slabs, online free slab design, design of slabs one way, free slab design online, Design Procedure for One Way Slab Skip to content Civil Engineers PK.

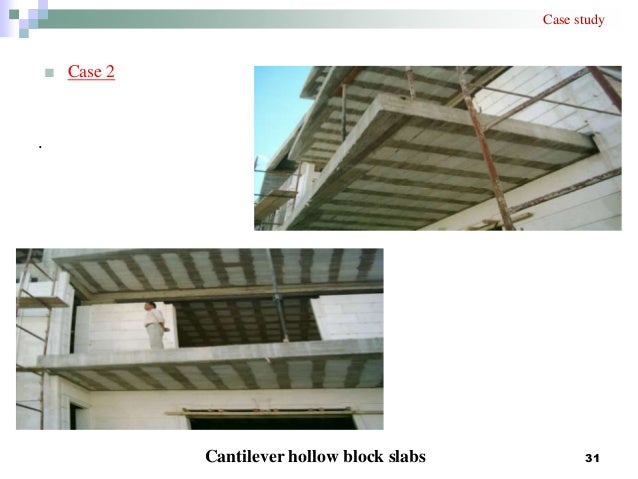

Analysis and Design of One-way Slab System (Part-I). part, cross ribs "one to three ribs " in one way ribbed slab when the length of these slabs are greater than 5 m to decrease the deflection of slab. The ribbed slab was analyzed exactly by finite element theory through SAP 2000 program. The model provides the actual behavior for ribbed slab by analyzing the structure as one-unite in two, The two-way waffle slab is provided with a bigger span as compared to the solid slab. The two-way waffle slab is economical when it is used in the modular or prefabricated form. 4-Two-way Slab with the Hollow Block. Two-way slab action is assumed in a ribbed floor made of the double-tee section (precast), in the ribbed floor with integral beams.

one way ribbed slab YouTube

ribbed slab design Beam (Structure) Road Surface. Ribbed (Waffle) Slab System. Ribbed floors consisting of equally spaced ribs are usually supported directly by columns.They are either one-way spanning systems known as ribbed slab or a two-way ribbed system known as a waffle slab. This form of construction is not very common because of the formwork costs and the low fire rating. A 120-mm-thick https://en.wikipedia.org/wiki/One-way_slab experimental study of multi-ribbed one-way composite slabs made of steel fibre, foam, and normal concrete yabo wang 1, h. t. liu2, g. f. dou3, c. h. xi4, l. qian5.

• slab layout is irregular and those not comply with the restrictions stated previously • where horizontal loading is applied to the structure • where partial loading patterns are significant because of the nature of the loading • high live load/dead load ratios. 4 Design Procedure The basic design procedure of a two-way slab system has five steps. 1. Determine moments at critical • slab layout is irregular and those not comply with the restrictions stated previously • where horizontal loading is applied to the structure • where partial loading patterns are significant because of the nature of the loading • high live load/dead load ratios. 4 Design Procedure The basic design procedure of a two-way slab system has five steps. 1. Determine moments at critical

Which Slab Is Better – Ribbed Slab Or Solid Slab (One Way Or Two Way): First of all, It depends on the use of the structure. Slabs are structural members forming floors and roofs in buildings. They may be solid of uniform thickness or ribbed with ribs running in one direction or two directions( waffles). Which Slab Is Better – Ribbed Slab Or Solid Slab (One Way Or Two Way): First of all, It depends on the use of the structure. Slabs are structural members forming floors and roofs in buildings. They may be solid of uniform thickness or ribbed with ribs running in one direction or two directions( waffles).

Comparison of One-way and Two-way slab behavior Economic Choices One-way Slab on beams suitable span 3 to 6m with LL= 3-5KN/m2. Can be used for larger spans with relatively higher cost and higher deflections One-way joist system suitable span 6 to 9m with LL= 4-6KN/m2. Deep ribs, the concrete and steel quantities are relative low STRUCTURAL RIBBED CONCRETE SLABS The CUPOLEX® floor slab can be fully or partially suspended on piles, stem walls or grade/edge beams. Additional reinforced internal ribs are then used in the slab by introducing PONTEX®, the structural CUPOLEX® accessory to provide a structure capable of spanning between foundations or piles.

The shear strength of one-way reinforced concrete ribbed slabs without stirrups in the ribs is still controversial when its estimate does not consider the contribution of the monolithic flange. To contribute to a better understanding of the behavior of these slabs were fabricated in the laboratory 8 3.2.3.1 One-way Ribbed Slab : In one-way ribbed slab, loads are transferred in one direction, and the main reinforcement is distributed in the same direction of the load. With accurate to temperature and shrinkage, minimum of 33 bars diameter will be used in both direction and crossing each other over the blocks ( practically ). Figure 3.2

STRUCTURAL DESIGN 2 RIBBED (JOIST), HOLLOW POT & WAFFLE SLAB DESIGN TO BS 8110 @Mr.Asish Seeboo 8 1.2 WAFFLE SLAB DESIGN 1.2.1 INTRODUCTION Similar to one-way slab, it is seen that the weight of a solid two-way slab can be appreciably reduced by eliminating portions of … Chapter 3: Analysis and Design of Two-way Slabs Page 4 simple beam, uniformly loaded by its share of q. because these imaginary strips actually are part of the same monolithic slab; their deflections at the intersection point must be the same. Equating the center deflections of the short and long strips gives 5544 384 l b EI (1) Where qa

05/11/2019 · one way and two way slab design programme Design Spreadsheets In high rise buildings and skyscrapers, thinner, pre-cast concrete slabs are slung between the steel frames to form the floors and ceilings on each level. • slab layout is irregular and those not comply with the restrictions stated previously • where horizontal loading is applied to the structure • where partial loading patterns are significant because of the nature of the loading • high live load/dead load ratios. 4 Design Procedure The basic design procedure of a two-way slab system has five steps. 1. Determine moments at critical

In this post, I will go over the sixth example in our course that covers the analysis and design of reinforced concrete one-way slabs. The objective of this reinforced concrete design example is to design a one ribbed concrete joist floor system per ACI Code 318-11. Continuous one-way slabs are analysed considering a frame of continuous member s of rectangular shape cross-section, having width equal to 1.00 m and height equal to the thickness of the slab. The strip loads comprise self-weight, dead and live loads.

ribbed slab design example pdf In order to demonstrate the application of the MathCAD program and to demonstrate its impact on teaching the analysis and design of two-way ribbed slabs.The number of strands in each rib is typically limited to one or two, with bottom rebar not exceeding two 5 12mm. Difference between One Way Slab and Two Way Slab SLAB: Slabs are constructed to provide flat surfaces, usually horizontal, in building floors, roofs, bridges, and other types of structures. The slab may be supported by walls, by reinforced concret...

8 one-way reinforced concrete ribbed slab panels where the main variables were the distance between the ribs and the thickness of the flange. The normative recommendations of NBR 6118, ACI 318 and EUROCODE 2 for the ultimate resistance of these slabs were evaluated. The experi - The slab is the flange of the beam and the extended part is the web. The extended part is known as ribs. The spacing between the ribs should be in general 20-30 inch. The ribs are tapered in cross-section in its lower part. Types of Ribbed and Waffle slabs. There are two types of …

06/12/2017 · basic of ribbed slab with aci 318-02 code requirements. it's also known as one way joist floor system. ribbed slab design in safe-part-1: https://www.youtube... 06/12/2017 · basic of ribbed slab with aci 318-02 code requirements. it's also known as one way joist floor system. ribbed slab design in safe-part-1: https://www.youtube...

Chapter 3: Analysis and Design of Two-way Slabs Page 4 simple beam, uniformly loaded by its share of q. because these imaginary strips actually are part of the same monolithic slab; their deflections at the intersection point must be the same. Equating the center deflections of the short and long strips gives 5544 384 l b EI (1) Where qa Ribbed slabs (One-way joists) Introducing voids to the soffit of a slab reduces dead weight and increases the efficiency of the concrete section. A slightly deeper section is required but these stiffer floors facilitate longer spans and provision of holes. Economic in the range 8 to 12 m. The saving of materials tends to be offset by some

Ribbed and Waffle Slabs Types Advantages Disadvantages

EXPERIMENTAL STUDY OF MULTI-RIBBED ONE-WAY COMPOSITE. Abstract. The simplest routine structural element for illustration of design provisions in the Code is the one-way slab. A one-way slab is defined for purposes of this book as a flexural member with depth small relative to other dimensions, supporting (gravity) loads applied normal to and directly over its surface, spanning in one direction, 3.2.3.1 One-way Ribbed Slab : In one-way ribbed slab, loads are transferred in one direction, and the main reinforcement is distributed in the same direction of the load. With accurate to temperature and shrinkage, minimum of 33 bars diameter will be used in both direction and crossing each other over the blocks ( practically ). Figure 3.2.

STRUCTURAL DESIGN 2 RIBBED (JOIST) HOLLOW POT

CHAPTER 3. ANALYSIS AND DESIGN OF TWO-WAY SLABS. part, cross ribs "one to three ribs " in one way ribbed slab when the length of these slabs are greater than 5 m to decrease the deflection of slab. The ribbed slab was analyzed exactly by finite element theory through SAP 2000 program. The model provides the actual behavior for ribbed slab by analyzing the structure as one-unite in two, Analysis and Design of Slabs, One way slabs, online free slab design, design of slabs one way, free slab design online, Design Procedure for One Way Slab Skip to content Civil Engineers PK.

ribbed slab design example pdf In order to demonstrate the application of the MathCAD program and to demonstrate its impact on teaching the analysis and design of two-way ribbed slabs.The number of strands in each rib is typically limited to one or two, with bottom rebar not exceeding two 5 12mm. Continuous one-way slabs are analysed considering a frame of continuous member s of rectangular shape cross-section, having width equal to 1.00 m and height equal to the thickness of the slab. The strip loads comprise self-weight, dead and live loads.

Mathematical structural analysis of one way ribbed slabs was introduced in this paper. The results of this analysis are compared with the results of the finite element method by SAP program. In SAP program, the model has been divided to frame elements "to represent ribs and beams" and shell elements "to represent the slab and solid part STRUCTURAL DESIGN 2 RIBBED (JOIST), HOLLOW POT & WAFFLE SLAB DESIGN TO BS 8110 @Mr.Asish Seeboo 8 1.2 WAFFLE SLAB DESIGN 1.2.1 INTRODUCTION Similar to one-way slab, it is seen that the weight of a solid two-way slab can be appreciably reduced by eliminating portions of …

Thermal Simulation for a Room with Solid and One-Way Ribbed Slab Using FEM. Conference Paper (PDF Available) · April 2017 Analysis and Design of One-Way Slab Systems 11 Prof. Dr. Qaisar Ali Reinforced Concrete Design –II Department of Civil Engineering, University of Engineering and Technology Peshawar For purposes of analysis and design, a unit strip of one way slab, cut out at right angles to the supporting beams, may be considered as a rectangular beam of unit width, with a depth h and a span l a as shown

STRUCTURAL DESIGN 2 RIBBED (JOIST), HOLLOW POT & WAFFLE SLAB DESIGN TO BS 8110 @Mr.Asish Seeboo 8 1.2 WAFFLE SLAB DESIGN 1.2.1 INTRODUCTION Similar to one-way slab, it is seen that the weight of a solid two-way slab can be appreciably reduced by eliminating portions of … View Ribbed_slab.pdf from MECHANICAL ME 201 at Jordan University of Science and Technology. One Way Ribbed Slab Analysis of One Way Ribbed Slab Area supported by one rib = (Ls) (s) Load for each rib

Ribbed slabs (One-way joists) Introducing voids to the soffit of a slab reduces dead weight and increases the efficiency of the concrete section. A slightly deeper section is required but these stiffer floors facilitate longer spans and provision of holes. Economic in the range 8 to 12 m. The saving of materials tends to be offset by some In this post, I will go over the sixth example in our course that covers the analysis and design of reinforced concrete one-way slabs. The objective of this reinforced concrete design example is to design a one ribbed concrete joist floor system per ACI Code 318-11.

STRUCTURAL RIBBED CONCRETE SLABS The CUPOLEX® floor slab can be fully or partially suspended on piles, stem walls or grade/edge beams. Additional reinforced internal ribs are then used in the slab by introducing PONTEX®, the structural CUPOLEX® accessory to provide a structure capable of spanning between foundations or piles. 3.2.3.1 One-way Ribbed Slab : In one-way ribbed slab, loads are transferred in one direction, and the main reinforcement is distributed in the same direction of the load. With accurate to temperature and shrinkage, minimum of 33 bars diameter will be used in both direction and crossing each other over the blocks ( practically ). Figure 3.2

Difference between One Way Slab and Two Way Slab SLAB: Slabs are constructed to provide flat surfaces, usually horizontal, in building floors, roofs, bridges, and other types of structures. The slab may be supported by walls, by reinforced concret... Minimum Depth. Minimum depth of the one-way concrete slab, most of the times is governed by deflection criteria. Sometimes the minimum depth is adequate as per flexure design, but if deflection criteria aren’t fulfilled such slabs will face vibration even under small loads like walking, jumping, etc.

Analysis of two- way ribbed and waffle slabs with hidden beams Article (PDF Available) in International Journal for Computational Civil and Structural Engineering Volume 4, No 3, 2014 · January 06/12/2017 · basic of ribbed slab with aci 318-02 code requirements. it's also known as one way joist floor system. ribbed slab design in safe-part-1: https://www.youtube...

Thermal Simulation for a Room with Solid and One-Way Ribbed Slab Using FEM. Conference Paper (PDF Available) · April 2017 3.2.3.1 One-way Ribbed Slab : In one-way ribbed slab, loads are transferred in one direction, and the main reinforcement is distributed in the same direction of the load. With accurate to temperature and shrinkage, minimum of 33 bars diameter will be used in both direction and crossing each other over the blocks ( practically ). Figure 3.2

Difference between One Way Slab and Two Way Slab SLAB: Slabs are constructed to provide flat surfaces, usually horizontal, in building floors, roofs, bridges, and other types of structures. The slab may be supported by walls, by reinforced concret... Analysis of two- way ribbed and waffle slabs with hidden beams Article (PDF Available) in International Journal for Computational Civil and Structural Engineering Volume 4, No 3, 2014 · January

Shear strength of reinforced concrete one-way ribbed slabs

Which slab is better one way or two way? Quora. Which Slab Is Better – Ribbed Slab Or Solid Slab (One Way Or Two Way): First of all, It depends on the use of the structure. Slabs are structural members forming floors and roofs in buildings. They may be solid of uniform thickness or ribbed with ribs running in one direction or two directions( waffles)., 14/12/2016 · One Way Slab. One way slab is supported on two opposite side only thus structural action is only at one direction. Total load is carried in the direction perpendicular to the supporting beam. If a slab is supported on all the four sides but the ratio of longer span (l) to shorten span (b) is greater than 2, then the slab will be considered as.

CHAPTER 3. ANALYSIS AND DESIGN OF TWO-WAY SLABS

STRUCTURAL ANALYSIS OF RIBBED SLAB. Difference between One Way Slab and Two Way Slab SLAB: Slabs are constructed to provide flat surfaces, usually horizontal, in building floors, roofs, bridges, and other types of structures. The slab may be supported by walls, by reinforced concret... https://en.wikipedia.org/wiki/One-way_slab The slab is the flange of the beam and the extended part is the web. The extended part is known as ribs. The spacing between the ribs should be in general 20-30 inch. The ribs are tapered in cross-section in its lower part. Types of Ribbed and Waffle slabs. There are two types of ….

The two-way waffle slab is provided with a bigger span as compared to the solid slab. The two-way waffle slab is economical when it is used in the modular or prefabricated form. 4-Two-way Slab with the Hollow Block. Two-way slab action is assumed in a ribbed floor made of the double-tee section (precast), in the ribbed floor with integral beams Minimum Depth. Minimum depth of the one-way concrete slab, most of the times is governed by deflection criteria. Sometimes the minimum depth is adequate as per flexure design, but if deflection criteria aren’t fulfilled such slabs will face vibration even under small loads like walking, jumping, etc.

Analysis of two- way ribbed and waffle slabs with hidden beams Article (PDF Available) in International Journal for Computational Civil and Structural Engineering Volume 4, No 3, 2014 · January Mathematical structural analysis of one way ribbed slabs was introduced in this paper. The results of this analysis are compared with the results of the finite element method by SAP program. In SAP program, the model has been divided to frame elements "to represent ribs and beams" and shell elements "to represent the slab and solid part

In this post, I will go over the sixth example in our course that covers the analysis and design of reinforced concrete one-way slabs. The objective of this reinforced concrete design example is to design a one ribbed concrete joist floor system per ACI Code 318-11. The two-way waffle slab is provided with a bigger span as compared to the solid slab. The two-way waffle slab is economical when it is used in the modular or prefabricated form. 4-Two-way Slab with the Hollow Block. Two-way slab action is assumed in a ribbed floor made of the double-tee section (precast), in the ribbed floor with integral beams

Analysis and Design of One-Way Slab Systems 11 Prof. Dr. Qaisar Ali Reinforced Concrete Design –II Department of Civil Engineering, University of Engineering and Technology Peshawar For purposes of analysis and design, a unit strip of one way slab, cut out at right angles to the supporting beams, may be considered as a rectangular beam of unit width, with a depth h and a span l a as shown 05/11/2019 · one way and two way slab design programme Design Spreadsheets In high rise buildings and skyscrapers, thinner, pre-cast concrete slabs are slung between the steel frames to form the floors and ceilings on each level.

Continuous one-way slabs are analysed considering a frame of continuous member s of rectangular shape cross-section, having width equal to 1.00 m and height equal to the thickness of the slab. The strip loads comprise self-weight, dead and live loads. 02/07/2015 · One-Way Concrete Slab Design Part 1 - Concept Explained and Minimum Slab Thickness - Canadian Code - Duration: 11:46. AF Math & Engineering 8,461 views

Thermal Simulation for a Room with Solid and One-Way Ribbed Slab Using FEM. Conference Paper (PDF Available) · April 2017 experimental study of multi-ribbed one-way composite slabs made of steel fibre, foam, and normal concrete yabo wang 1, h. t. liu2, g. f. dou3, c. h. xi4, l. qian5

Analysis and Design of Slabs, One way slabs, online free slab design, design of slabs one way, free slab design online, Design Procedure for One Way Slab Skip to content Civil Engineers PK Spanning one way between beams or walls Spanning two ways between the support beams or walls Flat slabs carried on columns and edge beams or walls with no interior beams Type of slab: One-way solid slab: Slabs of uniform thickness bending and reinforced …

14/12/2016 · One Way Slab. One way slab is supported on two opposite side only thus structural action is only at one direction. Total load is carried in the direction perpendicular to the supporting beam. If a slab is supported on all the four sides but the ratio of longer span (l) to shorten span (b) is greater than 2, then the slab will be considered as Which Slab Is Better – Ribbed Slab Or Solid Slab (One Way Or Two Way): First of all, It depends on the use of the structure. Slabs are structural members forming floors and roofs in buildings. They may be solid of uniform thickness or ribbed with ribs running in one direction or two directions( waffles).

Analysis and Design of Slabs, One way slabs, online free slab design, design of slabs one way, free slab design online, Design Procedure for One Way Slab Skip to content Civil Engineers PK Advantages of Ribbed and Waffle Slabs. In this type of slab, the tension stress is eliminated in the tension side of the slab. The strength of concrete in tension is very small and so elimination of much of the tension concrete is done by the use of pan forms.

Abstract. The simplest routine structural element for illustration of design provisions in the Code is the one-way slab. A one-way slab is defined for purposes of this book as a flexural member with depth small relative to other dimensions, supporting (gravity) loads applied normal to and directly over its surface, spanning in one direction STRUCTURAL DESIGN 2 RIBBED (JOIST), HOLLOW POT & WAFFLE SLAB DESIGN TO BS 8110 @Mr.Asish Seeboo 8 1.2 WAFFLE SLAB DESIGN 1.2.1 INTRODUCTION Similar to one-way slab, it is seen that the weight of a solid two-way slab can be appreciably reduced by eliminating portions of …

View Ribbed_slab.pdf from MECHANICAL ME 201 at Jordan University of Science and Technology. One Way Ribbed Slab Analysis of One Way Ribbed Slab Area supported by one rib = (Ls) (s) Load for each rib Difference between One Way Slab and Two Way Slab SLAB: Slabs are constructed to provide flat surfaces, usually horizontal, in building floors, roofs, bridges, and other types of structures. The slab may be supported by walls, by reinforced concret...