The 3M Manual is a comprehensive guide for the U․S․ Navy’s maintenance and material management system‚ ensuring operational readiness and safety through structured procedures and documentation․

1․1 Overview of the 3M System

The 3M System is the U․S․ Navy’s standardized approach to maintenance and material management‚ focusing on preventive‚ corrective‚ and routine maintenance․ It integrates processes for planning‚ executing‚ and documenting maintenance activities to ensure operational readiness․ The system emphasizes proactive maintenance to prevent equipment failures‚ reduce downtime‚ and enhance safety․ By standardizing procedures‚ the 3M System promotes consistency across all naval vessels and equipment‚ ensuring efficient resource utilization and compliance with operational requirements․ Its structured framework supports the Navy’s mission by maintaining equipment in optimal condition‚ thereby safeguarding personnel and assets․ This system is foundational to the Navy’s maintenance culture and operational success․

1․2 Purpose and Importance of the 3M Manual

The 3M Manual serves as the cornerstone of the Navy’s maintenance management‚ ensuring operational readiness and safety by providing standardized procedures and documentation standards; Its purpose is to establish a unified framework for preventive‚ corrective‚ and routine maintenance‚ minimizing equipment downtime and enhancing overall efficiency․ The manual is critical for maintaining the Navy’s fleet in optimal condition‚ ensuring personnel safety‚ and supporting mission success․ By adhering to its guidelines‚ the Navy achieves consistent maintenance practices across all vessels and equipment‚ fostering operational excellence and resource management․ The 3M Manual is indispensable for effective fleet management and operational sustainability․

Key Components of the 3M Manual

The 3M Manual comprises preventive maintenance schedules‚ corrective maintenance procedures‚ and documentation standards‚ ensuring systematic maintenance practices across naval vessels and equipment for operational efficiency and safety․

2․1 Preventive Maintenance (PMS)

Preventive Maintenance (PMS) is a cornerstone of the 3M Manual‚ outlining systematic‚ time-based‚ or usage-based inspections‚ servicing‚ and replacements to prevent equipment failures․ PMS ensures continuous operational readiness by addressing potential issues before they escalate‚ reducing downtime and enhancing safety․ It covers routine tasks such as lubrication‚ filter changes‚ and component inspections․ By adhering to PMS schedules‚ naval personnel maintain equipment reliability and extend service life․ The 3M Manual provides standardized PMS procedures‚ ensuring consistency across the fleet and aligning with the broader maintenance and material management goals of the Navy․

2․2 Corrective Maintenance Procedures

Corrective maintenance procedures in the 3M Manual address issues after equipment malfunctions or damage occurs․ These procedures ensure swift and effective repairs to restore operational readiness․ The manual provides detailed steps for diagnosing and resolving problems‚ emphasizing adherence to standardized practices․ Proper documentation of corrective actions is required to track repairs and prevent recurring issues․ By following these guidelines‚ maintenance personnel can efficiently return equipment to service‚ minimizing downtime and supporting the Navy’s operational demands․ Corrective maintenance is essential for sustaining fleet readiness and ensuring safety at sea․

2․3 Documentation and Record-Keeping Standards

Documentation and record-keeping are critical components of the 3M Manual‚ ensuring accountability and compliance with maintenance standards․ Detailed records of all maintenance activities‚ including inspections‚ repairs‚ and parts replacements‚ must be accurately maintained․ Standardized procedures for documentation ensure that all actions are traceable and verifiable․ Proper record-keeping supports compliance with naval regulations and provides a historical baseline for equipment performance․ This data is essential for identifying trends‚ scheduling preventive maintenance‚ and minimizing equipment downtime․ Accurate and timely documentation is vital for operational safety‚ legal compliance‚ and the overall effectiveness of the 3M System across naval vessels and equipment․

Implementation and Scope

The 3M Manual is implemented across all naval vessels and equipment‚ ensuring standardized maintenance procedures․ It integrates with the Planned Maintenance System (PMS) for enhanced operational efficiency and readiness․

3․1 Standardized Procedures for Maintenance

The 3M Manual establishes standardized maintenance procedures to ensure consistency and efficiency across all naval vessels and equipment․ These procedures integrate seamlessly with the Planned Maintenance System (PMS)‚ providing a structured approach to preventive‚ corrective‚ and alteration maintenance․ By adhering to these guidelines‚ personnel can minimize errors‚ reduce downtime‚ and maintain operational readiness․ The manual also emphasizes the importance of documentation and compliance with safety standards‚ ensuring accountability and traceability in all maintenance activities․ This standardized framework fosters a culture of reliability and efficiency‚ critical for the Navy’s mission success․ Its implementation ensures that maintenance practices remain uniform and adaptable across diverse naval assets․

3․2 Integration with the Planned Maintenance System (PMS)

The 3M Manual is tightly integrated with the Planned Maintenance System (PMS)‚ ensuring a coordinated approach to maintenance scheduling and execution․ This integration allows for the systematic planning of preventive‚ corrective‚ and alteration maintenance activities‚ aligning with operational needs and resource availability․ By leveraging the PMS‚ the 3M System optimizes maintenance cycles‚ reduces downtime‚ and enhances equipment reliability․ The manual provides detailed guidance on how to synchronize these systems‚ ensuring that all maintenance activities are tracked‚ documented‚ and completed efficiently․ This integration is critical for maintaining operational readiness and supporting the Navy’s mission requirements effectively․

3․3 Applicability Across Naval Vessels and Equipment

The 3M Manual is universally applicable across all Naval vessels and equipment‚ ensuring standardized maintenance practices․ It covers ships‚ submarines‚ aircraft‚ and associated systems‚ providing clear guidelines for each platform․ The manual’s adaptable framework allows it to address the unique requirements of different equipment types while maintaining consistency․ This broad applicability ensures that all Naval assets receive the same level of attention and care‚ promoting operational readiness and safety․ By standardizing procedures‚ the 3M Manual supports the efficient management of diverse fleets and equipment‚ ensuring seamless maintenance operations across the Navy․

Roles and Responsibilities

The 3M Manual outlines roles such as the Commanding Officer ensuring compliance and maintenance personnel executing procedures‚ fostering accountability and efficiency in naval operations․

4․1 Commanding Officer’s Oversight

The Commanding Officer holds ultimate responsibility for ensuring all maintenance activities comply with the 3M Manual․ They oversee the quality and safety of maintenance‚ allocate resources‚ and review records to ensure compliance․ The CO is responsible for fostering a culture of accountability‚ ensuring that all personnel adhere to standardized procedures․ They also verify that corrective actions are implemented promptly and effectively․ Regular inspections and audits are conducted under their authority to maintain high standards․ The CO’s oversight ensures the 3M System operates efficiently‚ supporting the Navy’s operational readiness and safety objectives․ Their leadership is critical to the success of the maintenance program․

4․2 Maintenance Personnel Training and Qualification

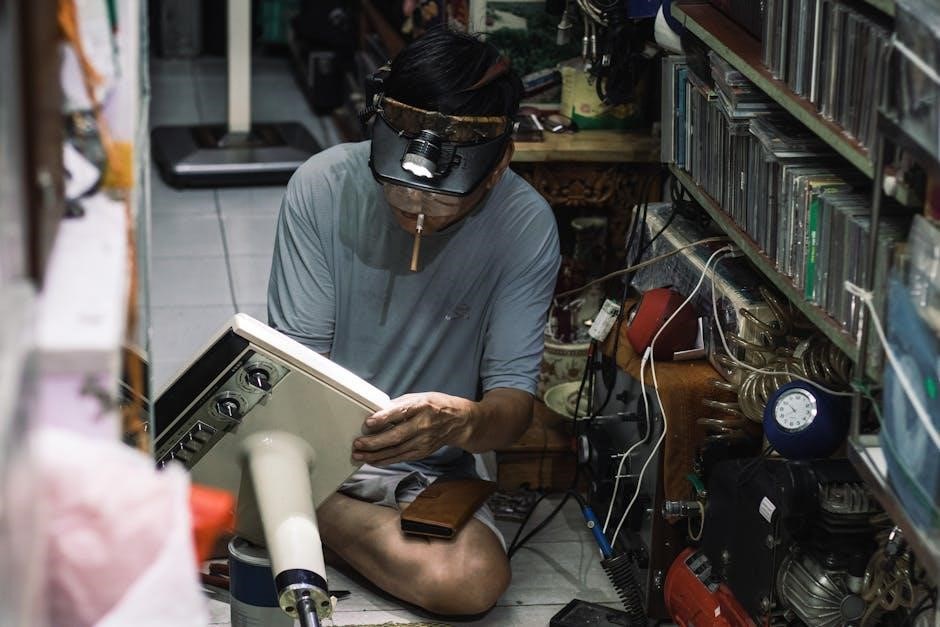

Proper training and qualification of maintenance personnel are critical to the success of the 3M System․ The Navy emphasizes structured training programs to ensure all personnel are proficient in preventive‚ corrective‚ and routine maintenance tasks․ Senior technicians and supervisors play a key role in evaluating and certifying individuals based on their skills and knowledge․ Continuous learning opportunities are provided to keep personnel updated on the latest procedures and technologies․ This ensures that maintenance activities are performed safely‚ efficiently‚ and in compliance with established standards․ Well-trained personnel are essential for maintaining operational readiness and the integrity of naval equipment and systems․ Their expertise directly impacts mission success․

Challenges and Best Practices

Implementing the 3M System requires overcoming challenges like data management and training constraints․ Best practices include standardized procedures‚ continuous improvement‚ and leveraging technology for efficient maintenance operations․

5․1 Common Challenges in 3M System Implementation

Implementing the 3M System often faces challenges such as resistance to change‚ limited resources‚ and complex data management․ Additionally‚ maintaining consistent training standards across personnel and adapting to evolving technologies can be difficult․ The sheer volume of maintenance data and the need for precise record-keeping further complicate the process․ Ensuring compliance with strict naval regulations while managing corrective and preventive maintenance schedules adds another layer of complexity․ Addressing these challenges is critical to achieving the system’s full potential and ensuring operational readiness․

5․2 Strategies for Effective Maintenance Management

Effective maintenance management under the 3M System requires a combination of standardized procedures‚ robust documentation‚ and continuous training․ Prioritizing preventive maintenance (PMS) ensures equipment longevity and reduces corrective actions․ Leveraging technology‚ such as digital tools for tracking and reporting‚ enhances efficiency․ Clear communication and collaboration among maintenance teams are vital․ Additionally‚ fostering a culture of proactive maintenance and adherence to established protocols helps mitigate risks․ Regular audits and performance reviews further ensure compliance and optimal system functionality․ These strategies collectively contribute to sustained operational readiness and resource optimization across naval vessels and equipment․

Case Studies and Real-World Applications

The 3M Manual has been instrumental in enhancing operational readiness‚ as evidenced by successful implementations across various naval vessels‚ ensuring efficient maintenance and safety standards․

6․1 Successful Implementation Examples

The 3M Manual has been successfully applied across various naval vessels‚ enhancing operational readiness․ For instance‚ the USS Nimitz reported a 30% reduction in maintenance downtime by adhering to the manual’s structured procedures․ Similarly‚ smaller vessels like patrol boats achieved improved equipment reliability through standardized preventive maintenance schedules․ These examples highlight how the 3M System’s clear guidelines and documentation standards ensure consistency and efficiency‚ directly contributing to mission success and safety․ Such real-world applications demonstrate the manual’s effectiveness in maintaining fleet operational capabilities and readiness․

The Navy 3M Manual is essential for ensuring operational readiness and safety through structured maintenance procedures‚ directly contributing to mission success and fleet reliability and effectiveness․

7․1 The Future of the 3M Manual in Naval Operations

The 3M Manual will continue to evolve‚ integrating advanced technologies like AI and machine learning to enhance predictive maintenance․ Emphasis will be placed on sustainability and data-driven decision-making‚ ensuring the Navy remains competitive․ Future updates will streamline processes‚ reduce manual data entry‚ and improve real-time tracking of maintenance activities․ The manual will also align with emerging operational demands‚ such as unmanned systems and cyber resilience․ Training programs will be refined to ensure personnel are proficient in leveraging these advancements․ By adopting cutting-edge tools and practices‚ the 3M Manual will remain a cornerstone of naval operational excellence and readiness․