Laser-guided machines, integrated with machine learning, enhance precision and adaptability in dynamic environments, enabling real-time data processing and intelligent decision-making across industries like manufacturing, healthcare, and beyond.

Overview of Laser-Guided Technology

Laser-guided technology utilizes precise laser beams to direct machines or systems, ensuring high accuracy in operations. Commonly applied in industrial and medical settings, it enables tasks like cutting, welding, and surgery with minimal human intervention. By projecting a laser beam onto a target, the technology provides real-time feedback, allowing machines to adjust their movements dynamically. This method is particularly effective in environments requiring millimeter-level precision. The integration of machine learning enhances this capability by enabling systems to interpret complex data, such as object detection and environmental adaptation. As a result, laser-guided technology has become indispensable in modern automation, offering reliability, efficiency, and scalability across diverse industries.

Role of Machine Learning in Precision Engineering

Machine learning plays a pivotal role in enhancing precision engineering by enabling systems to learn from data and improve performance over time. In laser-guided machines, ML algorithms analyze sensor data to optimize accuracy and adapt to complex environments. By processing vast datasets, these algorithms can identify patterns, predict anomalies, and refine operational parameters. This capability is particularly valuable in high-precision tasks, such as micromachining or robotic assembly, where even minor deviations can lead to significant errors. Moreover, ML facilitates real-time decision-making, allowing machines to adjust their operations dynamically in response to changing conditions. This integration of machine learning not only enhances the reliability of laser-guided systems but also enables them to achieve unprecedented levels of precision and efficiency.

Core Components of a Laser-Guided Machine

Laser-guided machines integrate advanced laser systems, machine learning algorithms, and sensor networks to enable precise targeting, real-time data processing, and adaptive control in various applications.

Laser Guidance System Architecture

Modern laser-guided machines employ a multi-layered architecture, combining high-precision laser optics, advanced sensors, and machine learning algorithms to achieve accurate targeting and control. The system typically includes a laser transmitter emitting a focused beam, a receiver capturing reflected signals, and a processing unit interpreting data. Machine learning models analyze this data to detect patterns, adjust targeting parameters, and optimize performance in real-time. This architecture ensures adaptability, enabling the system to function effectively in dynamic environments. Continuous learning from operational data enhances accuracy over time, making laser-guided systems indispensable in industries requiring high precision.

Machine Learning Algorithms for Precision Control

Machine learning algorithms play a pivotal role in enhancing the precision of laser-guided machines by enabling real-time adjustments and adaptive decision-making. Algorithms such as reinforcement learning and neural networks process sensor data to optimize laser targeting, ensuring minimal error margins. These systems learn from operational data to refine their accuracy over time, adapting to varying environmental conditions. For instance, reinforcement learning models can predict optimal beam alignment, while convolutional neural networks analyze visual data for precise object detection. By integrating these algorithms, laser-guided machines achieve unparalleled control, making them indispensable in applications requiring high accuracy and reliability.

Sensor and Data Acquisition Systems

Sensors are the backbone of laser-guided machines, capturing critical environmental data to enable precise operations. These systems integrate optical, infrared, and LiDAR sensors to detect and interpret target positions and movement. Real-time data acquisition ensures dynamic adjustments, allowing machines to adapt to changing conditions. Advanced sensor fusion techniques combine data from multiple sources, enhancing accuracy and reliability. Machine learning algorithms process this data to identify patterns and make informed decisions. High-resolution imaging sensors, for instance, enable object detection and tracking, while inertial measurement units provide positional awareness. Together, these systems form a robust framework for accurate and efficient laser guidance, critical in applications like industrial automation and medical robotics.

The Role of Machine Learning in Laser-Guided Machines

Machine learning enhances precision by enabling real-time data processing, pattern recognition, and adaptive learning, allowing laser-guided machines to operate effectively in dynamic and unpredictable environments.

Pattern Recognition and Object Detection

Machine learning algorithms enable laser-guided machines to excel in pattern recognition and object detection by processing visual data and identifying specific features or anomalies. These systems leverage advanced techniques like deep learning to analyze complex datasets, ensuring accurate and reliable detection. In real-time applications, such as industrial automation or medical robotics, this capability allows machines to dynamically adjust their operations based on detected patterns. The integration of point cloud data further enhances precision, enabling machines to understand spatial relationships and make informed decisions. This synergy between laser guidance and machine learning fosters highly accurate and efficient systems, capable of operating seamlessly in dynamic environments while maintaining exceptional performance standards.

Real-Time Data Processing for Accuracy

Real-time data processing is crucial for laser-guided machines to achieve high precision and accuracy. Machine learning algorithms process sensor data swiftly, enabling immediate adjustments and ensuring optimal performance. This capability is vital in applications like industrial automation, where milliseconds matter. By leveraging neural networks and edge computing, these systems minimize latency, allowing for faster decision-making. Continuous exposure learning enhances low-light conditions, improving reliability. JetFormer models streamline data processing, ensuring seamless integration of image and text inputs. This real-time capability ensures laser-guided machines operate efficiently, adapt dynamically, and maintain accuracy in demanding environments, making them indispensable in modern manufacturing and beyond.

Adaptive Learning for Dynamic Environments

Adaptive learning enables laser-guided machines to thrive in dynamic environments by continuously updating their models based on real-time data. Machine learning algorithms, such as neural networks, process sensor inputs to adjust to changing conditions, like varying workpiece dimensions or environmental factors. This adaptability ensures consistent accuracy and precision, even in unpredictable scenarios. Techniques like continuous exposure learning enhance performance in low-light settings, while JetFormer models optimize data processing for dynamic inputs. By integrating edge computing, these systems reduce latency and improve responsiveness. Adaptive learning allows laser-guided machines to evolve and improve over time, making them indispensable in industries requiring flexibility and high performance.

Applications of Laser-Guided Machines

Laser-guided machines are revolutionizing industries like manufacturing, healthcare, aerospace, and agriculture, offering precision, efficiency, and real-time data processing for complex tasks, enhancing productivity and accuracy significantly.

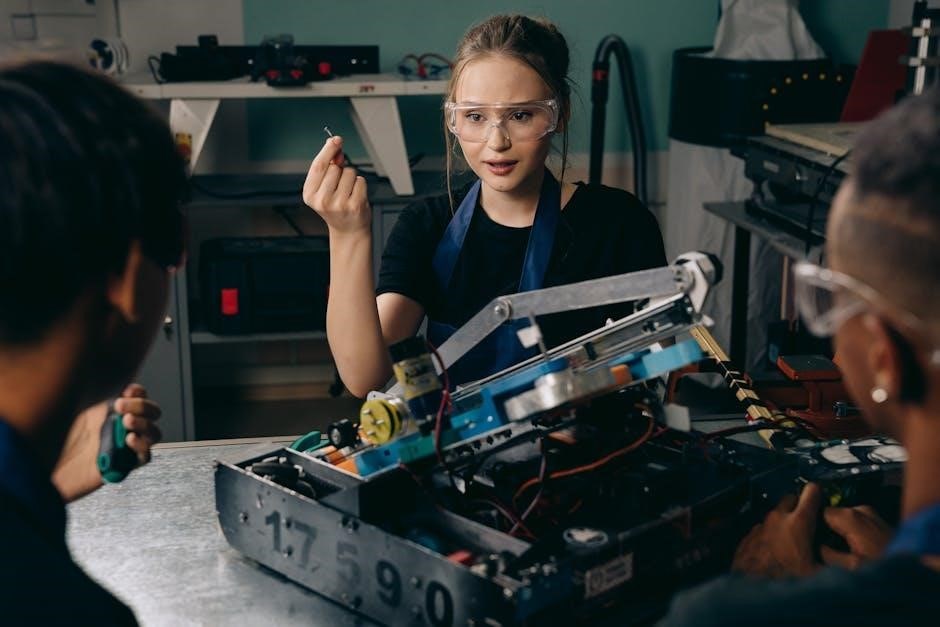

Industrial Automation and Manufacturing

Laser-guided machines, enhanced with machine learning, are transforming industrial automation by enabling precise real-time data processing and adaptive learning. These systems optimize manufacturing workflows, ensuring high accuracy and efficiency in tasks such as welding, cutting, and assembly. By integrating advanced algorithms, they can detect patterns and anomalies, reducing human error and increasing throughput. The ability to process complex data dynamically allows these machines to adapt to changing production demands, making them invaluable in modern manufacturing. Their precision and reliability have led to widespread adoption in automotive and electronics industries, driving innovation and productivity while maintaining high safety and quality standards. This integration of laser guidance and ML ensures factories operate smarter and more efficiently than ever before.

Medical Applications and Surgery

Laser-guided machines, combined with machine learning, are revolutionizing medical applications by enabling precise and minimally invasive surgical procedures. These systems use real-time data processing to enhance accuracy, reducing human error in critical operations. Machine learning algorithms analyze patient-specific data, allowing laser-guided robots to adapt to complex anatomical structures and dynamic surgical environments. Applications include tumor removal, ophthalmic surgeries, and neurosurgical interventions, where millimeter precision is crucial. The integration of ML improves surgical outcomes, reduces recovery times, and minimizes risks. This technology is also being explored for robotic-assisted surgeries, where pattern recognition and object detection capabilities further enhance surgical precision. The fusion of laser guidance and ML is transforming healthcare, offering safer and more effective treatments for patients worldwide. These advancements are paving the way for next-generation medical robotics and personalized surgical solutions.

Aerospace and Defense Systems

Laser-guided machines, enhanced with machine learning, play a critical role in aerospace and defense by enabling precise targeting and autonomous systems. These systems utilize real-time data processing to improve accuracy in missile guidance, drone navigation, and surveillance. Machine learning algorithms analyze complex patterns, allowing laser-guided weapons to adapt to dynamic environments and evade countermeasures. Applications include advanced missile defense systems, where ML optimizes trajectory planning and target recognition. Additionally, these technologies are integral to unmanned aerial vehicles (UAVs), enhancing their ability to perform reconnaissance and precision strikes. The integration of ML in laser-guided systems ensures robust performance in high-stakes scenarios, reducing human error and increasing operational efficiency. This technology is pivotal in modernizing defense infrastructure and maintaining strategic advantages in military operations. Its reliability and adaptability make it indispensable for future aerospace and defense applications.

Agricultural Automation

Laser-guided machines, combined with machine learning, are revolutionizing agricultural automation by enhancing precision and efficiency in farming tasks. These systems enable accurate weed control, pruning, and harvesting by detecting plant species and optimizing crop management. Machine learning algorithms process environmental data to adapt to varying conditions, such as weather changes or soil variations. Autonomous tractors and drones equipped with laser guidance can navigate fields with minimal human intervention, reducing labor costs and improving yield. Additionally, these technologies help in disease detection and fertilizer application, ensuring sustainable practices. The integration of ML in agricultural automation not only boosts productivity but also minimizes environmental impact, making farming more efficient and eco-friendly. This innovation is transforming traditional agriculture into a high-tech, data-driven industry.

Challenges in Implementing Machine Learning

Implementing machine learning in laser-guided machines faces challenges like data quality, computational complexity, and integration with existing systems, requiring robust solutions for reliable performance.

Data Quality and Noise Reduction

Data quality is critical for accurate performance in laser-guided machines using machine learning. Noise in sensor data can degrade model accuracy, requiring advanced filtering techniques. Environmental factors like dust or vibrations often introduce interference, complicating real-time processing. Machine learning algorithms must be robust to handle noisy inputs without compromising precision. Techniques such as signal smoothing, wavelet transforms, and noise reduction algorithms are essential to maintain data integrity. Poor data quality can lead to misclassifications or incorrect guidance, emphasizing the need for reliable preprocessing. Additionally, continuous monitoring and adaptive learning help systems adjust to dynamic conditions, ensuring optimal performance. Addressing noise effectively is vital for maintaining the reliability and safety of laser-guided systems in industrial and medical applications.

Computational Complexity and Latency

Machine learning in laser-guided machines faces challenges from computational complexity and latency, which can hinder real-time performance. Complex algorithms require significant processing power, potentially delaying response times. Latency issues are critical in applications demanding instantaneous reactions, such as industrial automation or medical robotics. To address this, lightweight ML models and optimized hardware are essential. Edge computing reduces latency by processing data locally, avoiding cloud delays. Efficient algorithms and parallel processing techniques further mitigate these challenges. Balancing computational demands with real-time requirements ensures precise and reliable operation of laser-guided systems. Addressing latency is crucial for maintaining accuracy and safety in dynamic environments. Optimized systems enable faster decision-making, ensuring operational efficiency and effectiveness across various applications.

Integration with Existing Laser Systems

Integrating machine learning with existing laser systems requires seamless compatibility to maintain performance. Legacy systems often lack the necessary interfaces for modern ML models, necessitating custom adaptations. Engineers must ensure that ML algorithms can interpret and process data from laser sensors accurately. Additionally, synchronization between ML processing and laser operation is crucial for real-time applications. Middleware solutions can bridge gaps between old and new technologies, enabling efficient communication; Testing and validation are essential to confirm that integrated systems function as expected. Successful integration enhances the capabilities of traditional laser systems, allowing them to leverage advanced ML-driven insights without compromising existing infrastructure. This harmonization is key to maximizing the potential of laser-guided machines in industrial and precision engineering contexts.

Case Studies and Real-World Examples

Case studies highlight real-world applications of laser-guided machines, showcasing their effectiveness in industrial automation, medical robotics, and autonomous systems, demonstrating improved accuracy and operational efficiency.

Success Stories in Industrial Automation

In industrial automation, laser-guided machines powered by machine learning have revolutionized manufacturing processes. A notable example is the implementation of ML-driven laser cutting systems, which achieved a 30% reduction in material waste and a 25% increase in production speed. Additionally, a DIY air defense system utilizing AI-powered laser turrets demonstrated real-time target detection and precision tracking, showcasing the technology’s versatility. These advancements highlight how machine learning optimizes laser-guided systems for enhanced accuracy, efficiency, and adaptability, transforming traditional manufacturing workflows into smarter, data-driven operations capable of handling complex tasks with minimal human intervention.

Applications in Medical Robotics

Laser-guided machines, enhanced by machine learning, are transforming medical robotics, enabling precise and minimally invasive surgeries. In prostate cancer treatment, ML-driven systems achieve 95% accuracy in tumor detection, reducing complications. Ophthalmic surgeries benefit from real-time adaptive learning, improving laser precision for cataract removal. These advancements highlight ML’s role in enhancing surgical outcomes, reducing recovery times, and minimizing human error, revolutionizing healthcare with smarter, data-driven tools.

Use in Autonomous Vehicles

Laser-guided machines, integrated with machine learning, are pivotal in autonomous vehicles, enabling real-time object detection and precise navigation. ML algorithms process LiDAR data for accurate obstacle recognition, ensuring safety and efficiency. These systems adapt to dynamic environments, improving decision-making in complex scenarios, and are essential for the next generation of self-driving technologies.

Ethical and Safety Considerations

Ethical use of laser-guided machines demands strict safety protocols, transparency in ML decision-making, and accountability to prevent errors and ensure compliance with regulatory standards.

Ensuring Precision and Avoiding Errors

Ensuring precision in laser-guided machines using machine learning requires robust calibration, advanced algorithms, and continuous validation. Errors can arise from data noise or model inaccuracies, necessitating rigorous testing and validation protocols. Real-time feedback mechanisms help detect anomalies, enabling immediate corrections. High-precision sensors and data acquisition systems play a critical role in maintaining accuracy. Additionally, ethical considerations demand transparency in ML decision-making to avoid unintended consequences. Regular updates and maintenance of ML models ensure they adapt to new conditions, minimizing errors over time. By integrating these measures, laser-guided machines achieve reliable performance, critical for applications in sensitive fields like healthcare and aerospace.

Ethical Implications of Autonomous Systems

The integration of machine learning in laser-guided machines raises ethical concerns, particularly regarding accountability and decision-making transparency. Autonomous systems must ensure fairness and avoid biases in their algorithms, as flawed logic could lead to unintended consequences. Questions arise about who bears responsibility for errors or misuse, highlighting the need for clear ethical frameworks. Additionally, the potential for autonomous systems to displace human workers or make life-critical decisions underscores the importance of balancing innovation with societal well-being. Ethical guidelines must address these challenges to foster trust and ensure that laser-guided machines are used responsibly across industries. Continuous dialogue among stakeholders is essential to navigate these complex issues.

Regulatory Frameworks and Compliance

Regulatory frameworks play a crucial role in ensuring the safe and ethical deployment of laser-guided machines using machine learning. Industries must comply with strict guidelines to address safety, privacy, and environmental concerns. For instance, aerospace and healthcare sectors face stringent regulations to prevent accidents and data misuse. Compliance involves adherence to standards like ISO certifications and FDA approvals for medical applications. Additionally, data privacy laws such as GDPR and CCPA impose restrictions on how machine learning systems collect and process data. As technology evolves, regulatory bodies are continuously updating frameworks to accommodate advancements in AI and laser-guided systems. Industries must stay informed and adapt to these changes to avoid legal repercussions and maintain public trust. Compliance also requires regular audits and transparency in system operations to ensure accountability and reliability.

Future Trends and Innovations

Future advancements in laser-guided machines will focus on integrating cutting-edge ML algorithms, enhancing real-time processing with edge computing, and developing more precise laser technologies for scalable applications.

Advancements in Laser Technology

Recent developments in laser technology have led to more precise and compact laser systems, enabling higher accuracy in guidance and control. Innovations in laser diodes and optics have improved beam stability and reduced size, making them suitable for integration into machine learning-driven systems. These advancements allow for real-time adjustments and enhanced performance in dynamic environments, as seen in applications like autonomous vehicles and medical robotics. Additionally, the integration of machine learning algorithms with laser systems enables adaptive learning, where the system can improve its accuracy over time by processing feedback from its environment. This synergy between laser technology and ML is driving innovation across various industries, ensuring more efficient and reliable solutions.

Integration with Emerging ML Algorithms

The integration of laser-guided machines with cutting-edge machine learning algorithms, such as neural networks and reinforcement learning, enhances their ability to process complex data and make precise decisions in real time. Advances in deep learning enable these systems to analyze patterns and adapt to changing environments more effectively. For instance, algorithms like transformers and convolutional neural networks (CNNs) improve object detection and tracking accuracy. Additionally, the integration of generative models allows for predictive maintenance and optimized system performance. These advancements ensure that laser-guided machines remain at the forefront of technological innovation, offering scalable and intelligent solutions across industries such as manufacturing, healthcare, and aerospace.

Edge Computing for Faster Processing

Edge computing plays a pivotal role in enhancing the performance of laser-guided machines by enabling faster data processing closer to the source. This reduces latency and improves real-time decision-making, critical for applications like object detection and tracking. By processing data locally, edge computing minimizes reliance on cloud servers, ensuring quicker response times and more efficient operation. Integration with machine learning algorithms allows these systems to analyze patterns and adapt dynamically. For instance, edge computing facilitates real-time adjustments in laser guidance, enabling precise corrections during high-speed operations. This technology is particularly valuable in scenarios requiring instantaneous feedback, such as medical robotics and autonomous vehicles, where delays could compromise accuracy and safety. Edge computing thus complements machine learning, driving innovation in laser-guided systems.