The Peterbilt 389 Service Manual is a comprehensive guide for owners and technicians, offering detailed instructions for maintenance, repair, and troubleshooting. It ensures optimal performance and longevity.

1.1 Importance of the Service Manual for Peterbilt 389 Owners

The Peterbilt 389 Service Manual is essential for owners and technicians, providing critical information for maintaining and repairing the vehicle. It ensures compliance with manufacturer specifications, preventing costly breakdowns and extending the truck’s lifespan. The manual covers routine maintenance, diagnostic procedures, and repair processes, empowering owners to address issues promptly. It also includes wiring diagrams, error codes, and parts catalogs, making it a one-stop resource for troubleshooting. By following the manual, users can ensure safety, optimize performance, and reduce repair costs. It is indispensable for anyone aiming to keep their Peterbilt 389 in peak condition and avoid potential operational disruptions.

1.2 Overview of the Manual’s Content and Structure

The Peterbilt 389 Service Manual is organized into clear sections, making it easy to navigate. It begins with an introduction, followed by detailed chapters on maintenance, repair procedures, and troubleshooting. The manual includes electrical schematics, wiring diagrams, and diagnostic codes to aid in identifying and resolving issues. Additional sections cover spare parts identification and catalog references, ensuring users can source genuine components. The structure is logical, with each chapter building on the previous one to provide a holistic understanding of the truck’s systems. This systematic approach ensures that users can quickly locate the information they need, whether for routine maintenance or complex repairs.

Maintenance and Repair Procedures

This section provides detailed maintenance schedules, repair processes, and diagnostic guidelines to ensure the Peterbilt 389 operates at peak performance and longevity.

2.1 Routine Maintenance Schedule for Peterbilt 389

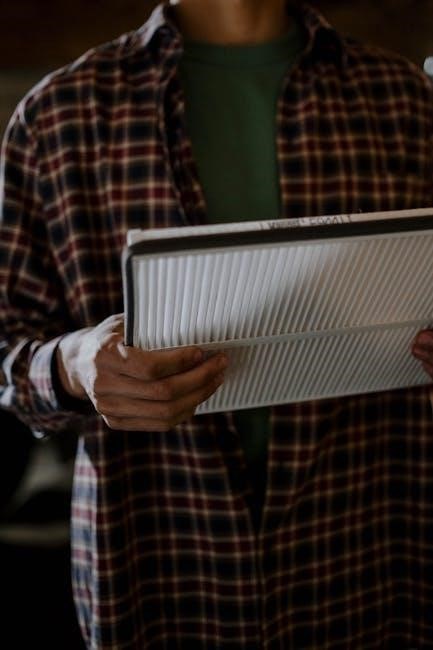

The Peterbilt 389 service manual outlines a detailed routine maintenance schedule to ensure optimal performance and longevity. It includes regular oil changes, tire rotations, and air filter inspections, all of which are critical for maintaining engine health. The manual specifies intervals for synthetic oil changes at 10,000 to 15,000 miles and conventional oil at 5,000 to 7,500 miles. Brake system checks, coolant replacements, and belt inspections are also emphasized to prevent premature wear. Adhering to this schedule helps reduce downtime, improves fuel efficiency, and ensures compliance with warranty requirements. Proper maintenance is essential for sustaining the truck’s reliability and operational efficiency over time.

2.2 Detailed Repair Processes for Common Issues

The Peterbilt 389 service manual provides in-depth repair processes for common issues, ensuring efficient troubleshooting and resolution. It covers engine overheating, transmission malfunctions, and electrical system faults, offering step-by-step solutions. For example, diagnosing coolant leaks involves checking hoses, radiators, and water pumps, while transmission issues may require inspecting fluid levels and replacing faulty solenoids. The manual includes detailed torque specifications, wiring diagrams, and parts replacement procedures. It also emphasizes the use of genuine parts and specialized tools for reliability. By following these guidelines, technicians can restore the truck to optimal condition, minimizing downtime and ensuring safety on the road.

Electrical Systems and Wiring Diagrams

The Peterbilt 389 service manual provides detailed electrical schematics and wiring diagrams, essential for diagnosing and repairing electrical issues. It covers circuits, connectors, and system components.

3.1 Understanding the Electrical Schematics

Understanding the electrical schematics in the Peterbilt 389 service manual is crucial for diagnosing and repairing electrical systems. The manual provides detailed wiring diagrams, showcasing connections, circuits, and components. These diagrams are color-coded and labeled for clarity, helping users identify specific wires and their functions. The electrical schematics cover systems like lighting, brakes, and electronic controls. They also include troubleshooting guides to trace faults efficiently. By familiarizing oneself with these schematics, technicians and owners can resolve electrical issues more effectively, ensuring the truck operates safely and efficiently. The manual emphasizes the importance of following proper procedures to avoid damage to sensitive electronic components.

3.2 Wiring Diagrams for Troubleshooting

The Peterbilt 389 service manual includes detailed wiring diagrams designed to simplify the troubleshooting process. These diagrams provide a visual representation of the truck’s electrical systems, highlighting connections, circuits, and components. By referencing these diagrams, technicians can quickly identify faulty wires, connectors, or modules. The manual also includes color-coded keys and symbols to enhance clarity. Troubleshooting sections often pair wiring diagrams with error codes and diagnostic steps, ensuring efficient resolution of electrical issues. This combination of visual and procedural guidance makes it easier to pinpoint and repair problems, reducing downtime and ensuring the truck returns to optimal operation as quickly as possible.

Troubleshooting Common Issues

The Peterbilt 389 service manual provides detailed guidance for diagnosing and resolving common problems, including error codes and diagnostic techniques to identify and repair issues efficiently.

4.1 Error Codes and Diagnostic Trouble Codes (DTC)

The Peterbilt 389 service manual includes a detailed list of error codes and Diagnostic Trouble Codes (DTCs) to help identify and address specific issues. These codes are categorized by system, such as engine, transmission, or electrical, and provide clear references for troubleshooting. By referencing the manual, users can interpret codes, understand their causes, and implement corrective actions. The guide also explains how to retrieve codes using diagnostic tools and outlines the steps to clear them after repairs. This section is essential for technicians and owners to diagnose problems efficiently and ensure the truck operates at peak performance. Regular updates and accurate code definitions make it a reliable resource.

4.2 Step-by-Step Diagnostic Techniques

The Peterbilt 389 service manual provides a structured approach to diagnosing issues, starting with identifying symptoms and retrieving error codes. Technicians can follow a sequential process: 1) review the problem description, 2) consult the troubleshooting chart, and 3) perform tests to isolate the fault. The manual includes detailed procedures for checking electrical circuits, testing components, and verifying system operation. It also covers the use of diagnostic tools and software to analyze data. By following these steps, users can efficiently pinpoint the root cause of problems, ensuring accurate repairs. This methodical approach minimizes downtime and ensures the truck returns to optimal operation quickly.

Spare Parts and Catalogs

The manual provides detailed spare parts catalogs, enabling precise identification of genuine components; It guides users on sourcing authentic parts for reliable repairs and maintenance.

5.1 Identifying and Sourcing Genuine Spare Parts

The Peterbilt 389 Service Manual includes a detailed parts catalog, making it easy to identify genuine components. Each part is listed with specific codes and descriptions, ensuring accuracy. Users can cross-reference diagrams to locate exact items needed for repairs. The manual also provides guidance on sourcing parts directly from authorized Peterbilt dealers or trusted suppliers. This ensures that all replacements meet factory standards, maintaining the truck’s performance and warranty. By following the catalog, owners and technicians can avoid counterfeit parts, reducing the risk of malfunction and extending the vehicle’s lifespan. Proper part identification is crucial for efficient and reliable maintenance.

5.2 Using the Parts Catalog Effectively

The Peterbilt 389 Service Manual includes a detailed parts catalog designed to help users quickly locate and identify components. Organized by system and component, the catalog features part numbers, descriptions, and diagrams for easy reference. Users can search by specific criteria, such as part number or system category, to streamline the process. The catalog also provides compatibility information, ensuring that selected parts match the truck’s specifications. By referencing the catalog, owners and technicians can efficiently order the correct parts, reducing downtime and ensuring proper repairs. This section emphasizes the importance of leveraging the catalog to maintain accuracy and efficiency in parts replacement.

Additional Resources for Peterbilt 389 Owners

This section explores additional resources, such as online communities, forums, and dealer support, providing Peterbilt 389 owners with comprehensive assistance and updates.

6.1 Online Communities and Forums for Support

Online communities and forums dedicated to Peterbilt 389 owners provide invaluable support and resources. These platforms allow owners to share experiences, ask questions, and access tips from experienced technicians and fellow drivers. Many forums are moderated by experts who offer guidance on troubleshooting and repair. Additionally, these communities often host downloadable resources, such as PDF manuals, wiring diagrams, and repair guides. Engaging with these groups can help owners resolve issues quickly and stay updated on the latest maintenance practices. They also serve as a hub for discussing new tools, parts, and technologies related to the Peterbilt 389, fostering a collaborative environment for mutual support.

6.2 Dealer Support and Authorized Service Centers

Dealer support and authorized service centers play a crucial role in maintaining and repairing the Peterbilt 389. These centers are equipped with certified technicians who have extensive knowledge of the truck’s systems and components. They provide access to genuine parts, specialized tools, and the latest diagnostic software, ensuring repairs are done to factory standards. Additionally, authorized centers often offer emergency service and priority scheduling for urgent issues. Owners can rely on these facilities for routine maintenance, complex repairs, and compliance with manufacturer recommendations. Their expertise ensures that the Peterbilt 389 operates at peak performance, minimizing downtime and extending its service life.